Crankshaft and Cross-shaft Assemblies and Chains

Bespoke Crankshafts

Replacing an original crankshaft

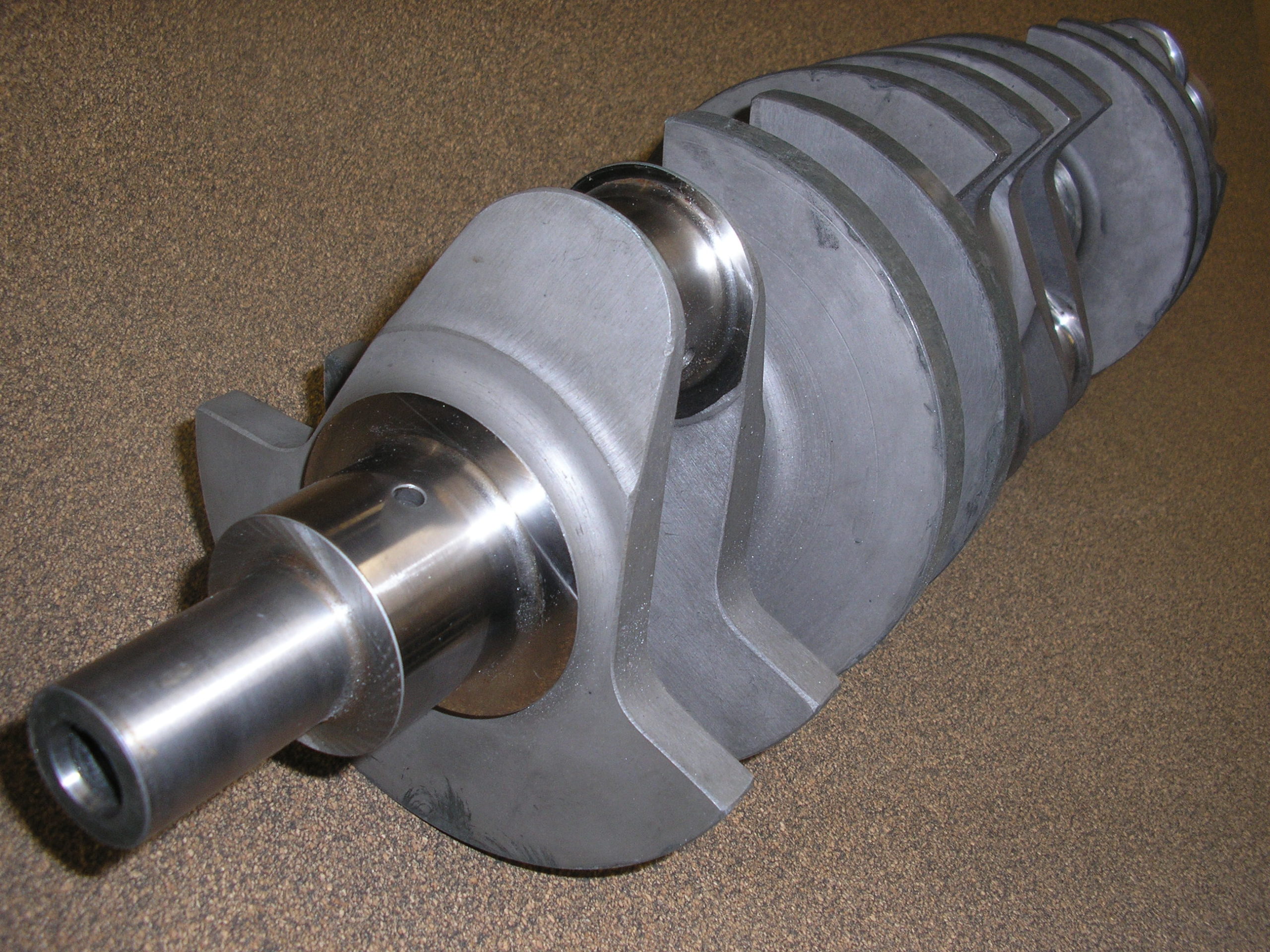

Although the AC crankshaft is not the frail, failure-prone item that some would have us believe, supplies of good, original shafts are finite and for those wishing to replace their original AC crankshafts, whether for reasons of wear or higher performance, we can supply bespoke, billet steel crankshafts and matching rod sets. The crankshafts are made to our specifications by a leading company in this field and may be ordered to suit Vintage, PVT UMB, post-war UMB, UMC and CL engines.

The crankshafts are designed to offer far greater strength than the original items and also have much stiffer, having shorter big-end journals than the original shafts.

Your block will require slight modification to accept the crank and substitute bearings, which we can undertake on your behalf.

The crankshafts are designed to accept our modern one-piece oil seal conversion and require one of our bespoke flywheels (which, unlike some of our competitors’ flywheels, come complete with starter ring gear). Front dampers are used with bespoke cranks although the early, damper type flywheel can be used via a special adaptor plate. Normal AC clutches are used, either in standard or heavy duty form.

Bespoke cranks are made to order and delivery times can vary so early ordering is recommended.

Bespoke Conrods

Replacements for original conrods

The bespoke conrods referred to above are most usually supplied with a steel crankshaft but may also be ordered for use with a standard AC crank in an engine with raised performance.

Each rod is supplied with a new small end bush to suit the AC gudgeon pin dimension and is notched to accept the shell big-end bearings. AC crankshafts must be ground to suit the sizes of the bearing shells.

Bespoke rods are made to order and delivery normally takes several weeks.

Crankshaft Adaptors

New life for original crankshafts

Use of these new adaptors has enabled a number of crankshafts to be retrieved that, although sound in other respects, might otherwise have had to be scrapped through faults in their original adaptors, such as damaged or ground out bearing journals or rusted or broken sprocket teeth. We have encountered several crankshafts on which a worn out No 5 bearing journal – the one that carries the load of the flywheel – has been built up by metal spraying that has subsequently developed cracks and splits or has become detached completely, leaving it free to rotate upon the crankshaft.

Traditional Type

The traditional type is a direct replacement for the original adaptor but with the advantage that it has no oil flinger or scroll, making it ready to receive a modern oil seal without further modification. The block and sump will require modification to accept the carrier for the oil seal.

Hub Type

The hub type of adaptor offers the same advantages as the traditional type but with the added bonus that having no flange allows oil seals to be changed without having to strip the engine first. A bespoke flywheel is required with this type of hub, allowing the possibility of considerable weight reduction.

Bespoke Flywheels and Start Ring Gear

Flywheels for all occasions

Our range of bespoke flywheels caters for a variety of applications, whether for fitting to one of our new steel crankshafts or to an original crank.

Note:

Bespoke flywheels cannot be used with crankshafts originally mated to damper flywheels unless the crank is modified to accept a front damper.

Although we normally keep some flywheels in stock, they are usually made to order according to the customer’s requirements.

Flywheels can be made to whatever weight is required, whether 20lbs (as per the later AC flywheels) standard or much lighter.

New life for original flywheels

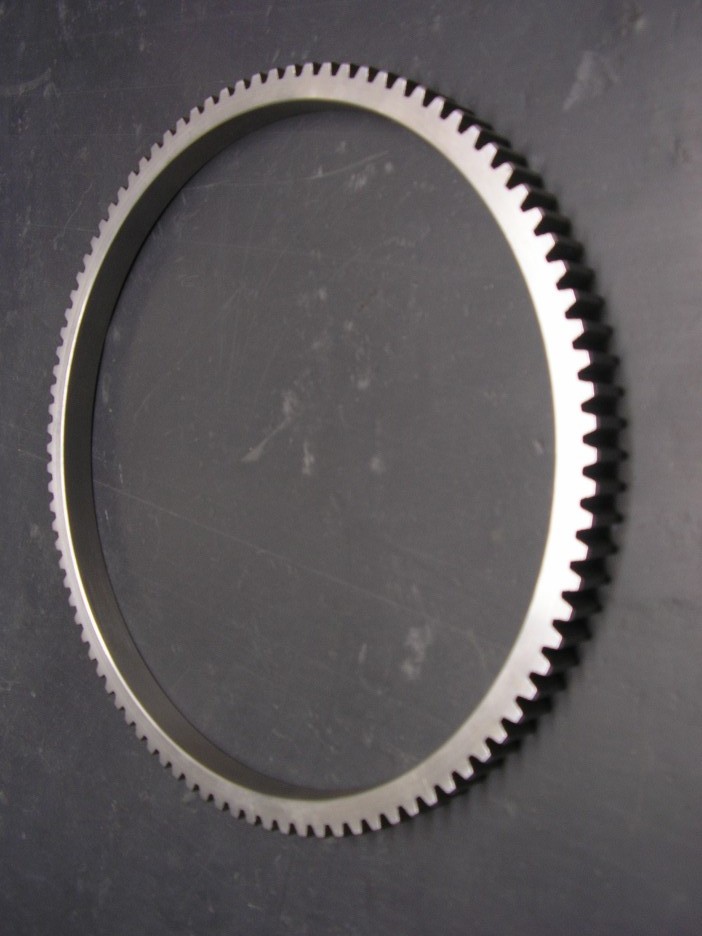

Many is the AC flywheel that has been scrapped because its ring gear was worn out, often with the teeth all but completely missing in one or more places. This has usually meant robbing the best used flywheel available from another engine.

Now however, we can supply new starter rings to fit your original flywheel. The old ring must be turned off the flywheel and the new one shrunk on and dowelled into place. We would be pleased to undertake this work on your behalf if required.

Clutch Assemblies

A new, exchange clutch assembly should certainly be fitted at engine overhaul, especially if the original friction plate is soaked in oil. Freedom from slipping and juddering can transform the feel of a car. The pressure plate should be balanced with the crankshaft and flywheel.

Engine Gear Sets

Usually supplied with bespoke crankshafts, a replacement gear set removes the slop and backlash in the drive to the distributor and makes accurate setting of the ignition much easier.

Cross-Shaft Shrouds

The cross-shaft shroud frequently becomes damaged over the years, usually through being left in place in the block during attempts to remove the rear cylinder liner. We have seen many smashed beyond further use.

Our new cross-shaft shroud solves this problem and restores one of the shroud’s main functions, which is to prevent excess oil from being flung up into the rear cylinder. Its design also lessens some of the frailties of the original design.

We can also supply complete cross-shaft assemblies i.e. with new shroud, shaft, spring, bearing, nuts and washers.

Timing Chains and Tensioners

The timing chain is a vital component in any engine and especially so in an AC engine where its considerable length means that excess wear can cause the chain to slap against the inside of the chain case and can allow the chain to jump the teeth of the crankshaft sprocket. A worn chain and a weak tensioner can jeopardise valve timing by falling to keep the camshaft in its correct relationship with the crankshaft. Chain and tensioner should always be renewed during engine overhauls.

Timing Sprocket Support Bracket

The support bracket in the post-war engines was a nasty affair pressed from thin, easily bent aluminium whereas the pre-war version was a nice, solid bronze or aluminium casting.

Our replacement for the post-war item is machined from solid and will not bend, enabling the timing sprocket to be slipped off the camshaft and properly supported until replaced.