What is an AC Engine?

Nearly a century…

Incredible though it may seem, within a few years we shall be celebrating the centenary of the AC Light Six engine.

This remarkable fact merits a moment’s reflection………it means that an engine designed at the end of the Great War enjoyed a production run of forty three years and is still in use in the 21st century and in forms recognisably deriving from that long ago original.

Ahead of its time…

What is it that makes the engine so special and so long-lived? Essentially, the design of the engine was so advanced for its time that it retained its technological lead for very many years. Even in the post second world war period it was unusual to find engines similarly specified. In fact, many family cars and a good number of those with sporting pretensions were still using engines with side valves, a far cry from the AC’s single overhead camshaft and inclined valves.

And beyond its time…

Eventually of course, even the brilliance of its design could not disguise the fact that the engine had reached the limits of its potential for development and had become too long in the tooth even for the AC Factory to perpetuate its use in their cars. Thus enter the Bristol engine and eventually the Zephyr…..but that is another story.

But still not out…

Despite their abandonment of engine manufacture, the Factory supported their old Six for many years with an excellent spare parts supply. Few manufacturers can have been so loyal to their customers for so long. Inevitably though, time caught up with even this lifeline; the Company changed hands and premises more than once and rationalisation made supplying spares in small quantities for such an old engine an economic nonsense and a distraction from the serious business of producing high powered sports cars for a very changed world market. Also, many of the small companies that had supplied parts to AC were themselves going out of business as the realities of economics overtook them.

The future beckons…

The lifespan of the engine however, was far from over and indeed, is brighter now that at any time since production ceased. And that is what this website is all about!

Design History

In the beginning…

Designed by John Weller under the leadership of SF Edge in 1919, the AC Light Six engine remained in production until 1963.

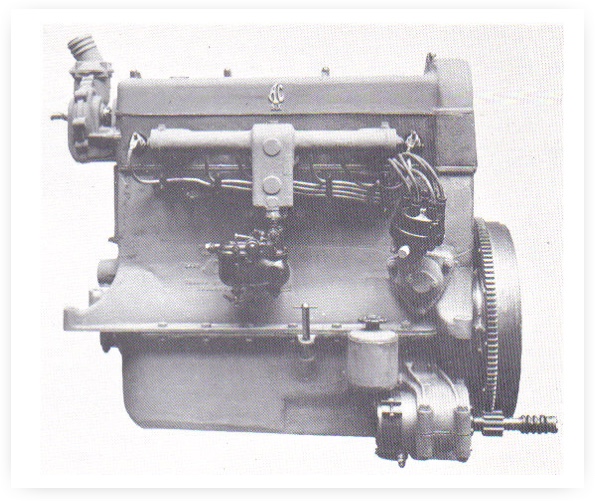

Although there were many improvements to the configuration of the engine during this astounding production run, the last engines were clearly identifiable with the very first, a tribute indeed to the soundness of the original, highly innovative design, with all engines sharing the same 1991cc capacity, a bore of 56mm and stroke of 100mm and wet liners in a light aluminium block. One feature of the engine, initially derided but later adopted by other makers, was the use of a long timing chain to drive the single overhead camshaft, chain tension being maintained by the Weller sprung blade. In the first engines that same camshaft also drove the water pump.

The starter motor has moved upwards, the flywheel is smaller in diameter, the water pump is now belt driven, the oil filler is in the rocker box and the engine now sports triple carbs (not shown).

The magneto and the dynamo were driven by either end of a cross shaft itself driven by a helical gear mounted behind the fourth main bearing of the crankshaft. The same helical gear also drove the shaft that turned the oil pump mounted low in the sump.

The forged iron crankshaft was initially carried in four white metal main bearings, the rearmost of which had to support the massive weight of a huge flywheel. The clutch was separate from the engine and mounted in the centre of the car, the three-speed gearbox being unitary with the rear axle. A single, updraught Stromberg carburettor provided the fuel.A new vibration…

A new vibration…

Its brilliant design notwithstanding, the engine did have some faults, notable amongst which was a tendency to vibrate at certain RPM. Lightening of the pistons, rods and crankshaft alleviated but did not cure the problem. Partial salvation came when Sydney Smith modified the rear end of the crankshaft by adding an adaptor that carried both an extra, fifth main bearing and the chain sprocket but the vibration was not fully cured until 1927 when Smith modified the flywheel by splitting it into two parts, the outer being mounted on the inner via a series of rubber rings, thus adding the function of a damper to the flywheel.

With the vibration issue behind them, AC were free to gradually, if somewhat conservatively, increase the power output of the engine. And it was this conservatism, coupled with poor trading conditions, that brought AC to its knees in 1929 when, refusing to update the by now hopelessly outmoded chassis and transmission of their cars, the receivers were called in.

New owners, new engines…

New life came when the Hurlock brothers took the company over, mostly for the premises but, from deciding that they might just as well complete the unfinished cars that they acquired, they eventually resumed car manufacture and introduced a range of supremely elegant and high performance vehicles.

Mechanically, the new cars were a great advance on their forbears as the ancient transaxle finally disappeared and the gearbox was now attached to the rear of the engine, thus necessitating changes to the rear of the crankcase casting. Although a conventional clutch was now employed in place of the earlier, centre mounted type, the split damper flywheel was retained and remained a feature of the engine for many more years. The single Stromberg carburettor layout was relegated to the status of an option whilst most cars were fitted with triple 11/8” SUs. The drive to the water pump was now via a conventional belt driven by a pulley at the front of the crankshaft and the magneto was replaced by a distributor. The new engines, of steadily increasing power, were numbered in the UMB prefix series. Some engines were supercharged. During the Thirties the inverted tooth timing chain was superseded by one of the Duplex type.

Plus ça change…

After WWII the AC engine was perpetuated in the Two Litre Saloon, the low bonnet line of which necessitated the moving of the water pump to the left hand side of the block, whilst engine mountings, formerly forward pointing, now faced sideways.

During the production run of the saloon, the UMB engine remained largely unchanged, the most significant modification being the final abandonment of the split damper flywheel in favour of a conventional, front mounted Metalastik vibration damper.

The post-war UMB engine shown here is the unit that one is most likely to encounter. It was fitted to the numerous Two Litre Saloons and to many early Aces and Acecas. The starter motor has moved upwards yet again and the water pump is now side-mounted.

A good number of Saloons have sacrificed their engines for fitting to PVT ACs, Frazer-Nashes and as replacements for worn out CL-series engines in Aces and Acecas.

Almost modern…

It was the introduction of the AC Ace and Aceca that spawned the last changes to the AC engine. Needing more power, the UMB engine was finally phased out in favour of the increasingly more powerful CL, CLB and CLBN series of power units, all having shell main and big-end bearings and 11/4” carburettors. Spurred on by lack of space in the Aces and Acecas, the dynamo migrated from its traditional position at the rear of the engine to a more normal, belt driven siting at the front of the engine. Power output had increased from an initial 40bhp for the very first engines to a claimed 110 for the last.

But not modern enough

However, although the AC engine had shrugged off some of its anachronisms and become almost conventional in detail, it remained at heart a vintage engine that had lived beyond its time, a dinosaur amongst emerging leaner, fitter and faster mammals. It could have been brought up to date. It could have been redesigned in line with contemporary trends with a shorter stroke and larger bore but such would have necessitated the completely new manufacture of just about every part of the engine. It just didn’t make economic sense, especially for a company as small as AC. It was far more cost-effective to outsource than re-design. Nonetheless, it was not until 1963 that the faithful old AC Six finally went out of production.

The Survivors

How many are left?

It is believed that a total of 2,750 cars with AC engines were produced. Allowing for spares (from which complete engines could and have been built), this could mean that about 3,000 engines altogether were made. Best estimates suggest that about 1,000 of these survive today, either running, under repair or salted down for a rainy day and ranging in condition from very good to total wreck, mostly the latter.

And the future

Reversing the decline…

Since founding AC Engines over ten years ago we have rebuilt so many engines that it is probably fair to say that not only have we halted the decline in the numbers of engines in use but have actually sent it into full reverse! Engines rescued from decay have been restored to health and a new life powering somebody’s treasured AC, Nash or other delectable machine.

Towards a brighter future

Indeed, the future for the engine has never looked brighter than at present. Whatever your engine problem, be it mechanical, the need for spares or just a lot more power, we can help you.

Call: 01458 273476

Email: [email protected]