Engine Rebuilds

Restoring it to health

The AC engine – dream or nightmare?

The venerable AC engine can be a source of delight or a fount of frustration. Well fettled, it is smooth, powerful and reliable. Neglected or bodged, it gives endless trouble. Blocks and cylinder heads corrode and crack, head studs snap, oil leaks past every seal, head gaskets fail and water gets into the oil. Eventually the thing refuses to run at all.

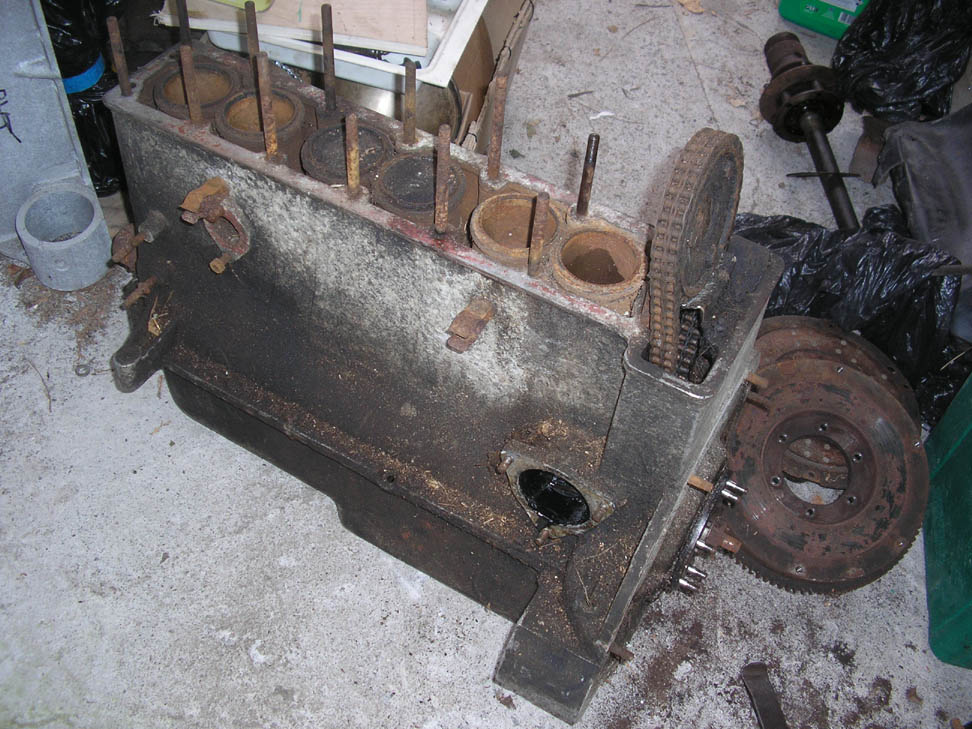

It is at this point that the unwary and perhaps still optimistic owner may lift his cylinder head in the expectation of finding nothing worse than a blown gasket. He may indeed find that but far more likely, he will also encounter a depressing mess of rotten aluminium, rusty studs and a veritable dune of silt rising from the base of the front cylinder to the top of the water jacket space at the rear of the engine.

This where the owner, now becoming seriously concerned, leans on the wings of his car and stares into the engine bay with a sense of rising hopelessness. If he has only recently bought the car, he now understands why it was for sale. The sight of huge quantities of red sealant around, on and under the head gasket provide evidence of the previous owner’s desperate attempts to solve the problem or at least to disguise it until the car was safely out his care.

At this stage many owners, convinced that the AC engine is inherently fragile and troublesome, give up in despair.

So what does it cost?

This is a perfectly reasonable question. Unfortunately there is no easy answer as final costs are, fairly obviously, based on the amount of work to be undertaken. We therefore provide estimates based on best and worst case scenarios for the job in question. We are not the cheapest on the market but we are a long from being the most expensive. We are always pleased to discuss an owner’s requirement.

Please note that we do NOT quote cheaply to land a commission and then, at the conclusion of the exercise, cold bloodedly present the customer with a litany of excuses to justify a grossly inflated bill e.g. ‘We just had to do this, that or the other…’. We do our best to keep the customer informed of all challenges during a rebuild, especially any likely to create unforeseeable extra expense.

A complete rebuild record

During each engine rebuild we e-mail the customer numerous written progress reports supported by copious quantities of photographs, usually numbering around 100. These may be supplied on CD upon request.

Owners are welcome to make an appointment to visit us to see how their engine rebuilds are progressing and to take photographs of their own if they so wish.

Facing up to it

No matter how well made or maintained, all engines wear out eventually and will need repair. The AC engine is no exception to this but its unique features can mean that its design is often imperfectly understood. This is an engine that cannot be treated just as any other, more conventional engine and many highly experienced and competent engineers have been known to either throw up their hands in horror when confronted with an AC engine or proceed only to find themselves bogged down.

Dealing with the problems

Dire as ownership can sometimes seem, most of the problems that afflict the AC engine are merely those of old age. There was little wrong with the original design – its 43 year production run speaks for itself. Unfortunately, it is those very innovative features that give the engine its uniqueness, notably the aluminium block and the wet liners, that lead to the problems described. While there was a good supply of reasonably priced second-hand engines in usable condition, it was possible – and certainly cheaper – to replace than to repair. Unhappily, engines so bought today are likely to be as troublesome as the ones they are destined to replace. Even if running, such engines are very likely to have been bodged to disguise the faults and all the the familiar problems will reappear in a fairly short time. Experience has shown that there is only one way to deal with an AC engine and that is thoroughly. Half measures simply will not do. And this is where we can help. And it need not cost the earth.

Despair is not an option

Giving up because the owner decides he has better things to do with his time and money is one thing; doing so out of despair is another entirely because there is not a problem that we cannot solve one way or another. We have never had to admit defeat yet and have brought many seemingly terminal cases back from the brink to provide reliable service and driving pleasure to their owners!

Overhauling an Engine

The first essential to any overhaul is to restore the block to sound condition. It is a complete waste of time carrying out any mechanical renovation unless the block is perfect. We have seen many engines where this imperative was ignored and with depressing and expensive consequences, usually involving water getting into the oil and damaging the engine internals, especially the bearings, devastating if they have have just been renewed.

Once your cylinder block has been restored, the rest of the engine can then be overhauled as required. In association with our carefully selected and proven suppliers we are able to provide the full range of overhaul services including:

- Chemical cleaning of engine components

- Crack testing of blocks, cranks, rods and heads

- Pressure testing of heads

- Crank grinding

- White-metalling and line boring

- Replacement of shell bearings on CL engines

- Cylinder re-boring

- Balancing of complete crank, damper, flywheel, pressure plate clutch assembly

- General machining and re-manufacture of broken parts

- Re-forming of stripped out threads

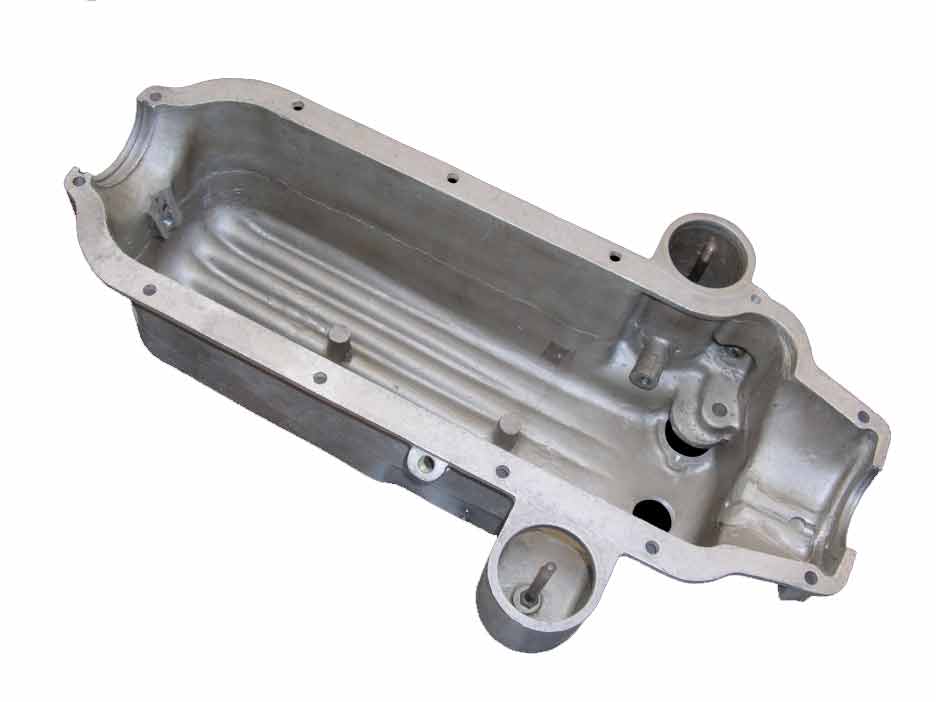

After chemical cleaning, requisite machining and repairs, blocks and sumps are scrubbed, pressure washed to remove swarf, air dried and inspected again to ensure absolute cleanliness before re-assembly of the engine.

After fitting, all moving parts are hand-operated to ensure correct movement and freedom from binding and tight spots.

And when it’s done…

All overhauled engines have the crucial block/head gasket/cylinder head joint hydro-pneumatically pressure tested for leaks, the rear oil seal checked for leaks and are then test run to ensure correct operation.

All engines are run for several hours and any necessary adjustments made so that when an engine is installed in a customer’s car, it should start instantly and run well right from the outset.

Putting things right...

Ready to collect

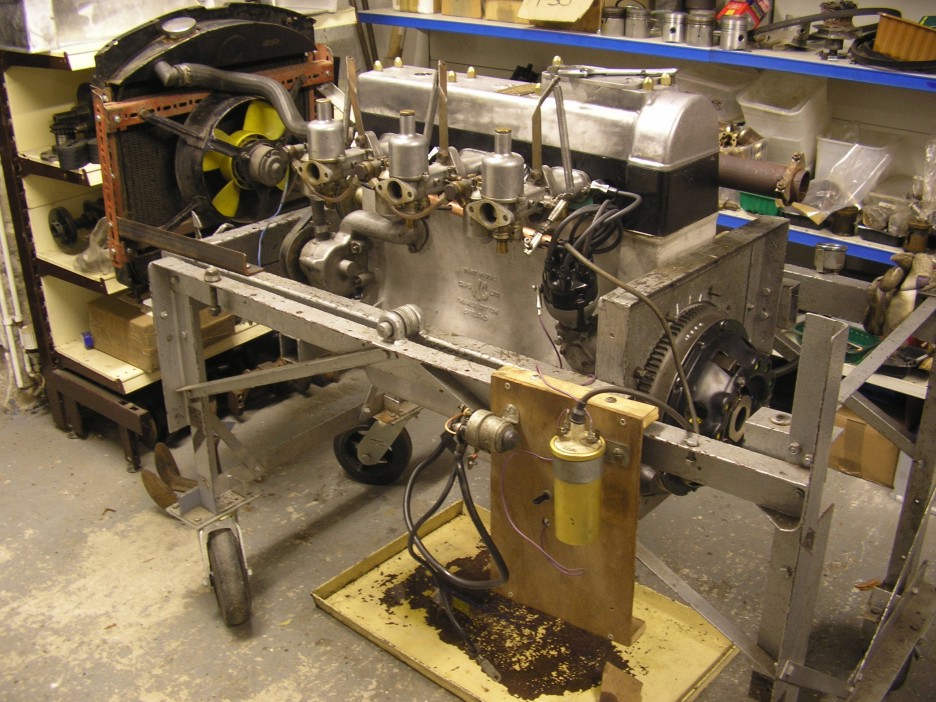

The picture to the left shows a completely rebuilt engine following a successful test run and awaiting collection by its owner.

Please note that the engine is still fitted with our test set of carburettors with which we normally run engines. We do not normally rebuild carburettors as this is more cost- effectively undertaken by a specialist company but we will be pleased to arrange this for you if required.

Engines built by us have powered Frazer-Nashes on the gruelling ‘raid’ to Bolzano including an ascent of the fearsome Stelvio Pass, PVT ACs on long Continental tours and cars of all eras in numerous competitive events including the taxing Mille Miglia on more than one occasion.